Steel is combination of iron, carbon (0.10 - 1%), manganese (<1.6%), Phosphorus (<0.6%), sulfur (<0.6%), silicon (<0.6%) and together with 20 + alloys. Alloys were added to molten steel to produce the steel of different characteristics.. say: hardness, tensile, ductility, toughness, etc.

Actually, steel products were produced in 3 stages:

1. Iron ore (hematite + Fe2O3 + magnetite + Iron carbonates + silicates + Sulfides) +coal +lime stone converted to Pig iron in blast furnace.

2. Pig iron to steel

3. Steel to steel products.

Classification of steels:

A. Mild steel or low carbon steel: carbon content of up to 0.25%.

B. Medium carbon steel or carbon steel: carbon content of 0.3-0.6%.

C. High carbon steels: carbon content of more than 0.6%.

D. Alloy steel: When elements other than Mn and Si are present.

E. Stainless Steel: When certain elements, such as Cr and Ni are added.

Steel shall be subjected to the following important test:

a. Tensile test

b. Torsion test - Shear modulus

c. Charpy V-Notch impact test - toughness

d. Bending test - Ductility

e. Hardness test

In construction, the steel is used as

a. Structural steel (Sections and pipes) - beam, columns, truss, frames, bracing, etc.

b. Reinforcement steel - reinforcement bars

Structural steel

Structural steel is used as Sections and pipes as follows:

a. American Standard Beam (S-Shaped) - S beam, S12x50 represents a beam that’s 12 inches deep and weighs 50 pounds per foot.

b. Angle (L-Shaped)- are typically used in floor systems because of the reduced structural depth.

c. Bearing Pile (H-Shaped) - bearing piles are H-shaped to effectively transfer loads through the pile to the tip. Bearing piles work best in dense soils that offer most resistance at the tip. Individual piles can bear more than 1,000 tons of weight.

d. Channel (C-Shaped) - C-shaped beams are cost-effective solutions for short- to medium-span structures. Channel beams were originally designed for bridges, but are popular for use in marine piers and other building applications.

e. Hollow Steel Section (HSS) - Metal profile that has a hollow, tubular cross section. HSS units can be square, rectangular, circular, or elliptical. HSS structures are rounded, with radius that are about twice the thickness of the wall. These are commonly use HSS sections in welded steel frames for which units experience loading in different directions.

f. I-Beam - I Beam, also known as an H beam or a universal beam, very effective at carrying shear and bending loads in the web’s plane.

g. Pipe - Structural steel pipes are important for a variety of construction applications, lending strength and stability. Pipes are hollow, cylindrical tubes that come in a variety of sizes, used to meet the needs of water, oil, and gas industry projects.

h. Tee - A T beam is a load-bearing beam with a T-shaped cross section can withstand large loads but lack the bottom flange of the I Beam, giving it a disadvantage in some applications.

i. Custom Shapes - Today structural steel is not limited to using only the most common shapes. Custom metal fabrication opens the doors to a variety of special structural steel shapes for any type of project.

Reinforcement steel

Reinforcing steel is manufactured in different forms as follows:

A. Un-coated steel

1. Mild steel ribbed bars

2. High Yield Strength Deformed (HYSD) bars

3. Cold-twisted deformed (CTD) bars (TOR steel)

4. Thermo Mechanically Treated (TMT) or Quenched & Self-Tempered (QST) steel

5. Stainless steel

6. Prestressing steel

B. Coated steel

1. Epoxy coated steel: Straight and bend bars can be applied with epoxy coating. Bars must be bent before epoxy-coating is applied. Bars shall be made free from rust before applying epoxy coating. Multiple layers of epoxy coating may be required, at least 2 coats. This will work in terms of Fusion bonded. In case, cutting happens after the coating, make sure to coat at the end also.

It is more dangerous to use damaged epoxy-coated steel than conventional un-coated steel

2. Galvanized steel: Initial stable corrosion product with Calcium hydroxyzincate (at pH < 13.3). Zinc’s corrosion products are loose, powdery minerals that are less voluminous than iron corrosion products and are able to migrate away from the galvanized rebar surface into the adjacent concrete matrix. As a result, corrosion of the zinc coating causes very little physical disruption to the surrounding concrete.

Substantially higher chloride threshold (2-4 times) for zinc coating. Zinc has a much greater pH passivation range than steel, making galvanized rebar resistant to the pH lowering effects of carbonation as the concrete ages. Even when the zinc coating does start to corrode, its corrosion rate is considerably less than that of uncoated steel.

C. Fiber Reinforced Polymer (FRP) bars / laminates

Lets us go in detail:

(CTD) Cold Twisted Deformed bars OR TOR (Toristeg Steel Corporation of Luxembourg) bars:

CTD bars are produced by twisting in cold condition. Higher strength and lower elongation and ribs improve the bonding with the concrete. Corrosion is an issue - so CTD bars are no longer use due to

poor corrosion resistance. Available in dia of 6, 8 10, 12, 16, 20, 25, 28, 32, 36, 40 and 45mm. They are used in min concrete grade of M15.

Thermo Mechanically Treated (TMT) or Quenched & Self-Tempered (QST) steel:

After hot rolling to the desired size and shape, the low carbon steel bars are quenched with water and then cooled. Quenching (The act of extinguishing; causing to stop burning) converts the surface layer to (hard) martensite while the core remains as austenite (A solid solution of ferric carbide or carbon in iron; cools to form pearlite or martensite). As the bar cools, heat flows from the core to the surface layer turning it to tempered martensite (A solid solution of carbon in alpha-iron that is formed when steel is cooled so rapidly that the change from austenite to pearlite is suppressed; responsible for the hardness of quenched steel). The core transforms to ductile ferrite-pearlite.

Further to TMT bar, Corrosion Resistant Steel (CRS) TMT reinforcement has developed. Bars with small quantities of copper and chromium,

and higher than usual percentage of phosphorus. i.e., Carbon – 0.15%, Manganese – 1%, Sulphur – 0.04%, Phosphorous – 0.10%, Silicon – 0.45%, Corrosion resistant elements – 0.50% (minimum).

Stainless steel reinforcement

Stainless steels are alloys that contain at least 12%

of chromium. Other alloying elements such as nickel and

molybdenum may also be present.Chromium oxide layer forms on the stainless steel

surface to prevent corrosion. These steels offer good resistance to corrosion as

long as the passive film can be maintained.

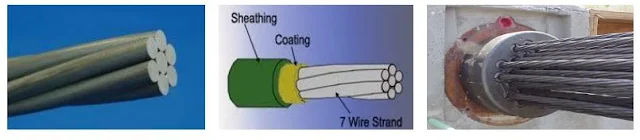

Prestressing steel reinforcement – wire strands / Threaded bar:

A high tensile alloy steel bar which

features a coarse right-hand

thread over its full length. Hot rolled, quenched and

tempered, followed by cold

working and further tempering, to

achieve the necessary

performance. 1000 hour stress relaxation is

typically less than 3.5%.

Glass-Fiber-Reinforced-Polymer (GFRP)

GFRP is made up of carbon fibre. As it is made up of fibre, bending is not allowed. It is very resistant to corrosion and is costly when compared to other rebars. Now a days GRPF panels were also made both in cast-in-suit or pre-cast.

How to identify the bars at site level?

> The first letter or symbol identifies the producing mill.

> The next marking is the bar size.*

> The third marking symbol designates the type of reinforcing steel — usually either "S" for > carbon-steel (ASTM A615) or "W" for low-alloy steel (ASTM A706).

> Finally, there will be a grade marking (60, 75, 80, 100, 120) or by the addition of one line (60) or two lines (75), three lines (80, 100), or four lines (120) that must be at least five deformations long.

In other country:

Splicing Bar

Reinforcement bars comes in specified length. All RCC structure are constructed in monolithic manner and hence the reinforcement bars shall be in continuous so that they can transfer the load uniformally without break in between. Hence, bars needs to joined and the joining the bars is called as Splicing bar.

Grades:

The reinforcement steel bars used in RCC (Reinforced Cement Concrete) are known as Fe415 or Fe500. The numbers 415 and 500 is the Yield Strength in N/mm2.

As per IS:1786 - Yield Stress (also known as 0.2% proof stress).

Ex: Fe 500 is the reinforcement bars that can safely withstand a Yield Stress of 500 N/mm2 which is stronger than 415 N/mm2 by~20%.

Somethimes, we see Fe500D, here “D” represents ductility. and these bars are used at High-rise Buildings which needs more flexibility in building to avoid brittle failure.

Grades of Rebar in Different Codes:

| American Standard (ASTM A 615) | Euro Standard(DIN 488) | British Standard BS4449: 1997 | Indian Standard (IS: 1786) |

| Grade 75 (520) | BST 500 S | GR 460 A | Grade Fe – 415, Fe – 500, Fe – 500D |

| Grade 80 (550) | BST 500 M | GR 460 B | Grade Fe – 550 |

Mild steel bars grade-I designated as Fe 410-S or Grade 60.

Mild steel bars grade-II designated as Fe-410-o or Grade 40.

Medium Tensile Steel Bars designated as Fe- 540-w-ht or Grade 75.

Corrosion-Resistance Bars

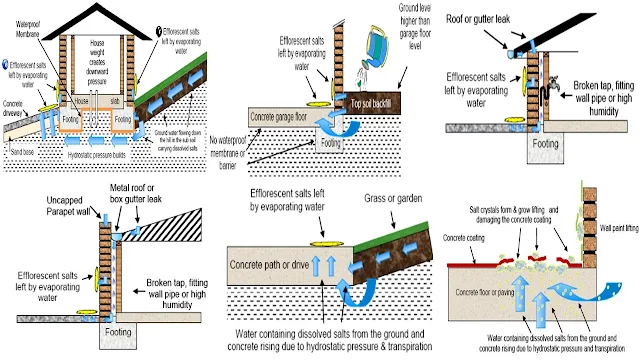

Corrosion of reinforcing steel may occur sue to the following reasons:

a. pH of the concrete is decreased from chemical attack or from reaction of the concrete with CO2 in the atmosphere.

b. Sufficient chloride ions reach the bar.- from deicing salts or sea water.

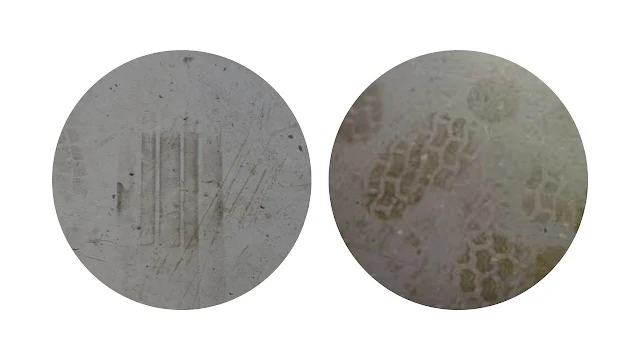

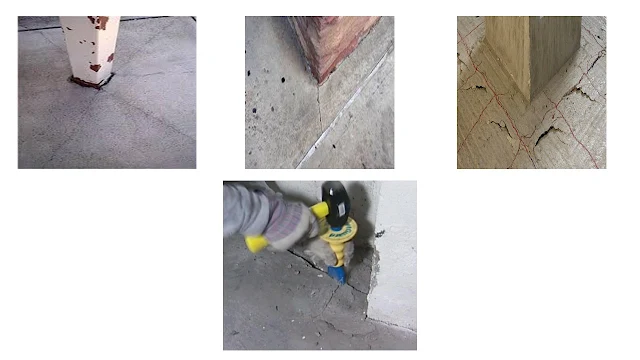

If steel corrodes in concrete it may cause cracking or spalling of the concrete.

Hence, it is good to use bar with Improved Corrosion Resistance. Such as Stainless Steel Bars, Galvanized Steel Bars or Epoxy-Coated Reinforced Bars.

As per ASTM, bar designations with improved corrosion resistance over uncoated Bars as follows:

a. ASTM A767/A767M: Zinc-Coated (Galvanized) Steel Bars for Concrete Reinforcement

b. ASTM A775/A775M: for Epoxy-Coated Reinforcing Steel Bars

c. ASTM A934/A934M: Epoxy-Coated Prefabricated Steel Reinforcing Bars

d. ASTM A955/A995M: Deformed and Plain Stainless-Steel Bars for Concrete Reinforcement

e. ASTM A1035/A1035M: Deformed and Plain, Low-carbon, Chromium, Steel Bars for Concrete Reinforcement

But, we have saw many structure standing from 100 years made with normal steel - How?

When steel is placed into concrete of high pH value, it develops a passive oxide film. This passive film prevents further corrosion of the steel and there are many examples where common reinforcing steel in concrete has remained un-corroded for over 100 years.

Why to use TMT bars over HYSD and CTD/TOR steel:

1. Due to the ductile micro-structure and a hard crystalline exterior surface of TMT bars, TMT bars have a stronger external layer as compared to HYSD steel bars.

2. TMT bars have less residual stresses and higher tensile strength than HYSD bars because TMT bars do not undergo any physical deformation, unlike HYSD bars.

3. As TMT bars do not undergo any physical deformation (twisting), no torsional stress occurs which removes the chances of surface defects in TMT bars.

4. Due to the reduced amount of surface defects in TMT bars as compared to HYSD steel, they are comparatively much less susceptible to the harmful effects of oxidation like corrosion.

5. TMT bars do not require explicit hardening as the hardening process is conveniently achieved by the water quenching process, thus reducing the energy and expenditure required for physically deforming the steel bars, and hence increasing their affordability.

6. Due to the amazing flexibility and durability exhibited by TMT bars, they can be used for a wide range of construction works and is basically one of the primary reasons why construction workers rely a lot more on TMT bars as compared to HYSD steel bars.

7. Using TMT bars for construction helps to reduce the consumption of steel by 8% to 11% as compared to HYSD bars for the same construction, again increasing their affordability.

8. As TMT bars have a uniform and hardened periphery and a considerably softer core, this kind of bars will have the desired tensile strengths coupled with high elongation and ductility as required in the construction of buildings located in areas with regular seismic activity.

9. TMT bars provide a longer life to the structures where they are used. The TMT steel inside the concrete does not react with the moisture in the surroundings. This reaction when allowed to occur results in the formation of rust which acts like cancer and results in cracks in the concrete, thus weakening the structure and subsequently shortening the lifespan of structures and buildings.

Quantity surveying and steel in construction.

Cost Ratio (C.R.) for steel and concrete:

The ratio between the cost of two parts or components involved in a work is known as Cost Ratio, shortly termed as C.R. Rate of steel per.cu.m. is taken as 62.5 times the cost of concrete as prevailing in India.

So, cost ratio or C.R. for steel and concrete is Cost of steel per Cu.M / Cost of concrete per M = 62.5

Weight of 1 cu.m. steel (Tor or plain) = 7850 kg. Cost@8.40 per kg = Rs.65940

Cost of 1 cu.m. of concrete M15 (1:2:4) for R.C.C. work = Rs. 1050

Therefore, Cost Ratio for steel and concrete = Rs.65940/Rs.1050 = 62.8

Please note: Price of larger diameter bars is also lower than of smaller ones. The basic price is that of 16 mm bars, all larger bars being priced at this rate while smaller bars cost proportionately more for each 3 mm diameter below 16 mm. But this should be remembered that for cutting and bending, bars of 25 mm diameter and larger, oxy-acetylene flame or power operated machine may be used. Bars upto 8 m length can be easily transported and handled. Bars upto 10 mm diameter can be obtained in long lengths in coils.

Prof. BN Dutta, for estimating steel for different components of a building is provide with some thumb rules as follows (this may be used for pre-tending works not for execution work):

a. Footing - 0.8% of concrete

b. Beam - 2% of concrete

c. Column - 5% of concrete

d. Slab - 1% of concrete

How to read the steel section?

Parts of sections:

Bar Bending Schedule:

Bar bending schedule commonly known as BBS is one of the most important term in Civil Engineering. Like other building materials like cement, brick, stones, tile, etc., estimation of steel is also required for constructing a building. Bar bending schedule provides the reinforcement calculation not only for the costing for quantity surveyors but also helps to bar bending works with important details such as bar mark, bar diameter, bar shape, cutting length, number of bars, the weight of bar, total weight of steel etc.Bar bending schedule (or schedule of bars) is a list of reinforcement bars for a given reinforced concrete work item, and is presented in a tabular with bars – diameter, shape of bending, length of each bent and straight portions, angles of bending, total length of each

bar, and number of each type of bar.

How to read the bars drawing?

Definition of bars:

Main reinforcement bar

1. Main reinforcement bar is to provide at the shorter span direction.

2. Main reinforcement bars at the bottom of the slab for taking all the tensile stresses, bending moment (Sagging), and superimposed load (Dead load) which developed at the shorter span of the slabs.

3. Dia of the main reinforcement bars are higher.

4. In one way slab, the slab is supported at two parallel sides where main reinforcement will be placed parallel to the support.

4. In two way slabs, the span will be supported at four ends. So there won’t be any difference in bar size. Because each side will have to transfer the same amount of stress evenly.

Distribution bars

a. Distribution bars are used to resist the shear stress, cracks developed in the longer span.

b. Distribution bars perpendicularly on top of the main bars.

c. Lesser dia is used as it is only to resist the cracks developed due to shear stress on top of the slab.

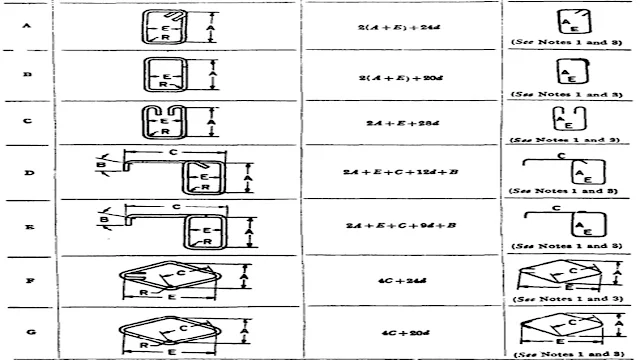

Stirrups:

Stirrups will be required at areas of high shear, such as bearing points and below large point loads, to reduce the need for additional piers. The deeper the beam, the more shear capacity. When the depth is not adequate, steel stirrups must be added to increase the shear capacity of the beam.

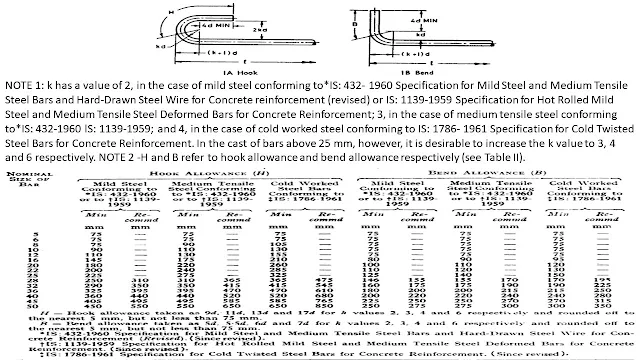

Hook Length:

The hook is the extra length left at the 4th corner of a stirrup so that the stirrup retains its shape. Generally, hook length is taken as 9d for one side.

Stools:

Stools are used to separate the top reinforcement mesh and bottom reinforcement mesh using (in general) 12 mm or 16 mm bars. Dimension of the Stools could be change as requirement. Those should be strength enough to bear the loads without changing the gap of two layers.

Stools:

Stools are used to separate the top reinforcement mesh and bottom reinforcement mesh using (in general) 12 mm or 16 mm bars. Dimension of the Stools could be change as requirement. Those should be strength enough to bear the loads without changing the gap of two layers.

Different lengths:

Development length: Development length is the length of bar required for transferring the stress into concrete. The quantity of the rebar length that is actually required to be embedded into the concrete to create the desired bond strength between steel and concrete and furthermore to produce required stress for the steel in that area.

Development length (Ld) = d x σs/τbd

Where as,

d = Diameter of the bar.

σs = Stress in the bar at the section considered as design load

τbd = Design bond stress.

Lapping length:Lap length is the overlapping length of two bars side by side which gives required design length. In RCC structure if the length of a bar is not sufficiently available to make design length, lapping is done. Suppose we need to build a 20 m tall building. But is there any 20 m bar available in the market? No, the maximum length of rebar is usually 10 / 12 / 12.5 m, so we need to join two bars to get 20m bar.

Suppose we need to build a 20 m tall building. But is there any 20 m bar available in the market? No, the maximum length of rebar is usually 10 / 12 / 12.5 m, so we need to join two bars to get 20m bar.

Lap length for tension members = 40d.

Lap length for compression members = 50d.

Crank length: Length of the bar at change in direction or bend length.

Anchor Length: Length of the bar extended in to the vertical member from the horizontal member for better holding. In the above drawing, Anchor length = 150- (Cover (i.e 25 mm)+ dia of bar 20mm = 145mm

BEND LENGTH:

The bar is bent at the column end to tie with the footings. This extra length for bend is called bend length. Bend length is generally considered as 16d

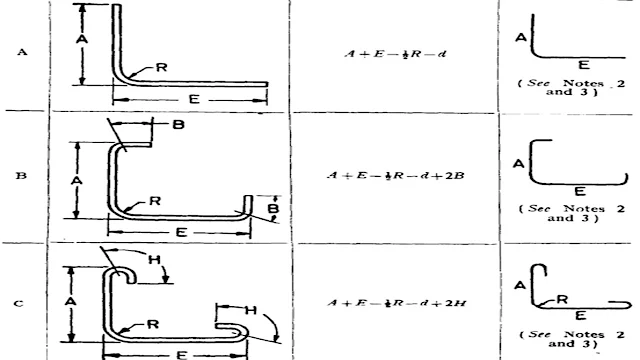

Bend Deduction Length Of Bar: The straight length of the bar is equal to the exact length of the bar. When we bend the bar, the length of the bar slightly increased due to stretching in the bending area. The expansion of length depends on the grade of steel and the degree of bend. The length increases with the increase of bending degree and decreases with the higher grade steel. Bend with different angle will have different expansion in length. Hence, to calculate the total length of the bar which has bends in it, we need to duct the expansion of the bar, this is called bend deduction length. Refer the below image:

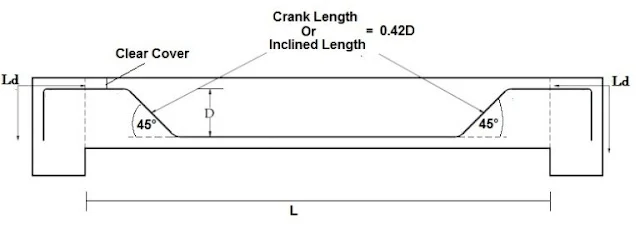

CRANK LENGTH:

Generally, bars are bent near the support at an angle of 45°. The angle of bend may also be 30° in shallow beams. The purpose of bend near the support is firstly to resist the negative bending moment which occurs in the region of the support and secondly to resist the shear force which is greater at the support. Crank length = D/sin45° – D/tan45° =1.42D – D = 0.42D

UNIT WEIGHT OF STEEL:

The weight of bar is calculated by the following formula: W = d²L/162

Where W = Weight of bars.

L = Length of bars in meter.

d = Diameter of the bar in mm.

Example: Calculate the weight of 20 meters long 16 mm ø bar

W = 16² x 20/162 = 32 kg.

Let see the formula to find the reinforcement bars:

The following are based on "Indian Standard - CODE OF PRACTICE FOR BENDING AND FIXING OF BARS FOR CONCRETE REINFORCEMENT - IS:2502-1963 (Reaffirmed 1990)'

Download this ready to start the Bar Bending schedule: https://drive.google.com/file/d/1SlYk_exbdwIit8F1JIoHTew16CA40EFt/view?usp=sharing

Checklist for site engineer for reinforcement:

1. Structural Dwg. No. and date as per which reinforcement checked. Bar Bending Schedule Prepared?

2. Connecting of bars to existing dowels to be checked for alignment. OK?

3. Placing of Bar diameter, number, spacing match with the Construction Schedule?

4. Lap Length, Position of lap, OK?

5. Cleanliness of shuttering and Bars OK?

6. Chairs provided?

7. Cover for reinforcement ok?

8. Provision of cover blocks/ preparation of cover blocks.

9. Maintaining records and getting approval for additional reinforcement not shown.

10. To check the construction joint for proper concrete bonding before placing reinforcement.

11. Installed bars of required dia.

12. Check for Test Reports for steel and approved brand or not.

13. Check colour coding for identification.

14. Check for proper binding (double strand/quality of binding wire).

15. Check for any rework or alteration.

Many thanks to Google.com, Doc88.com, Indian Institute of Technology Madras, aonesteelgroup.com, Wordweb.com, crsi.org, from where the details were collected.