This

blog explains about:

TYPICAL SURFACE PROBLEMS

WHY TO DO SURFACE PREPARATION?

NORMAL PROCEDURE OF SURFACE PREPARATION

MECHANICAL METHODS OF

SURFACE PREPARATION

WHICH TYPE OF SURFACE

FOR WHAT?

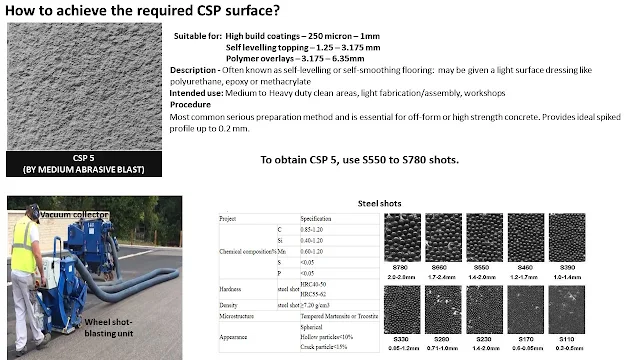

HOW TO ACHIEVE THE

REQUIRED CSP SURFACE?

ACID ETCHED PROCESS

GRINDING PROCESS

LIGHT SHOT-BLASTING PROCESS

LIGHT SCARIFICATION PROCESS

MEDIUM ABRASIVE BLAST PROCESS

MEDIUM SCARRIFYING PROCESS

SCABBLED PROCESS

HEAVY SCARIFICATION PROCESS

SURFACE CLEANING PROCESS - USING DEGREASER

SURFACE CLEANING PROCESS - HIGH PRESSURE WATER PROCESS

SURFACE CLEANING PROCESS - HIGH PRESSURE WATER

BLASTING & JETTING PROCESSLet see which standard say what about the surface preparation:

Reference the following industry standards for preparation of concrete from the ASTM International (formerly known as

American Society for Testing and Materials-ASTM), NACE International (formerly National Association of Corrosion

Engineers), Society for Protective Coatings (SSPC), and the International Concrete Repair Institute (ICRI):

ASTM D4258, Standard Practice for Surface Cleaning Concrete for Coating

ASTM D4259, Standard Practice for Abrading Concrete

ASTM D4260, Standard Practice for Liquid and Gelled Acid Etching of Concrete

ASTM D4261, Standard Practice for Surface Cleaning Concrete Unit Masonry for Coating

ASTM D7682, Standard Test Method for Replication and Measurement of Concrete Surface Profiles Using Replica Putty

SSPC-SP13/NACE 6, Surface Preparation of Concrete

ICRI Standard 310.2 Selecting and Specifying Concrete Surface Preparation for Sealers, Coatings, Polymer Overlays,

and Concrete Repair with CSP Chips.

Let us see a video to understand this very clearly:

For more details on the machines shown on the video, please visit:http://www.edcoinc.com/

No comments:

Post a Comment