NAUTRE…. The only source from which we get the

energy like heat and cold including natural materials like stone / soil

containing chemical. We modify / formulate the natural material or by mixing it

with other natural materials to make one more material for the specific use

called products. Nature provides light energy from which other resources like hot,

cold, water, high / low temperature, humidity, moisture will form in the

environment. Products invented from the nature will again use to protect other man-made

creations like house, roads, bridges, industries, etc to from the nature. So it

is very necessary for understanding the effects of nature on the products in

the time frame.. say before / while / after application.

Let see some of the affect of nature on our structures:

For study purpose, I am referring some

of the major types of products in some category as follows:

Tiling & grouting

|

Waterproofing

|

Flooring

|

Concrete repair

|

Polymer

based cementitious adhesives

|

Acrylic cementitious

LAM

|

Cementitious

flooring & screed

|

Cementitious

structural grout

|

Epoxy

based adhesives

|

Acrylic LAM

|

Epoxy

flooring & screed

|

Cementitious expanding

grout admix

|

Furane

based adhesives

|

Crystalline LAM

|

Polyurethane

flooring & screed

|

Polyester resin

anchoring grout

|

Polymer

based non-sanded grouts

|

Elastomeric LAM

|

Cementitious

epoxy flooring

|

Structural epoxy grout

|

Polymer

based sanded grouts

|

PU based LAM

|

Epoxy

based PU flooring

|

PU injection grout

|

Epoxy

based grouts

|

PU based acrylic LAM

|

Epoxy

coating

|

PU injection foam

grout

|

Furane

based grouts

|

Water based epoxy LAM

|

Polyurethane

coating

|

Cementitious polymer

structural mortar

|

Sealers

|

Rubber based SAM

|

Urethane

coating

|

Cementitious micro

concrete

|

Cleaners

|

Polyproline SAM

|

Water

based epoxy coating

|

Shuttering oil

|

|

|

Solvent

based epoxy coating

|

Oil based mould

release agent

|

|

|

Solvent

free epoxy coating

|

Wax based concrete

curing compound

|

|

|

|

Epoxy bonding agent

|

|

|

|

Anti corrosive epoxy

zinc rich primer

|

|

|

|

Non metallic floor

hardener

|

|

|

|

Acrylic copolymer

based admixture for concrete and mortar

|

|

|

|

SBR based liquid

polymer additive for concrete and mortar

|

|

|

|

Integral cement

waterproofing compound

|

|

|

|

Polyurethane joint

sealant

|

|

|

|

Acrylic crack filler

|

|

|

|

Cement based crack

filler

|

|

|

|

Epoxy resin based

adhesive and repair compound

|

Let see how the nature may create the

problems to the products and how it can be overcome:

1. Climate

/ Temperature: Let see at

how much temperature we the different climates and what will be the effect on

the environment.

Temperature °C

|

What might be at this temp

|

How it feels

|

Other points of interest

|

-30 (that is 30 degrees below

zero)

|

Ice, freezer

|

ICE

|

Very cold if you are outside in

this temperature, unbearable to most

|

-10

|

Ice

|

Snow fall

|

Very cold still but bearable if in lots of warm clothes

|

0

|

Water freezes, ice melts

|

Cold

|

Typical coldest average temperature

for UK in winter

|

4

|

Fridge

|

Cold

|

Water has its smallest volume at

this temperature

|

10

|

|

Cold

|

|

15

|

|

Cool

|

|

20

|

Room indoors

|

Warm

|

|

25

|

Warm room

|

Warm to hot

|

Typical maximum temperature for

British summer

|

30

|

Hot day

|

Feeling hot

|

Typical temperature for hotter

countries

|

37

|

Body temperature

|

Very hot

|

This is the average human body

temperature

|

40

|

Washing machine setting for clothes

for normal wash

|

Very hot

|

If you are outside in this

temperature you will feel hot, but more so if humidity is high.

If your internal body temperature reaches this level you are in danger of

death.

|

50

|

|

Extremely hot

|

Not many places get this high in

temperature, and this heat you would need to find shade, drink water and stay

cool.

|

60

|

Washing machine setting for hot

wash

|

Too hot to live in

|

Most bacteria die at this

temperature

|

90

|

Washing machine setting for hottest

wash

|

Too hot to live in

|

Humans cannot survive such high

temperatures

|

100

|

Water boils in the kettle

|

Water in tea maker

|

Water turns to steam

|

1000

|

Lava from a volcano

|

Rising valcano

|

|

1535

|

Melting point of iron

|

Iron plant

|

At this temperature iron will turn

into liquid form, to be used in industrial manufacturing processes

|

2750

|

Boiling point of iron

|

Blast furnace

|

The temperature at which iron boils

and vapourises

|

5500

|

Surface of the Sun

|

THE SUN

|

|

15 000 000

|

Core of the Sun

|

|

a. Cool climate: Applied product can

affected by the ambient temperatures and humidity, both at the high and low

ends of the range. So, to achieve optimal results users of products need to

make some adjustments in normal procedures to allow for these material

properties. In the winter, the combination of cold temperatures and increased

humidity produce one set of conditions which impedes curing, whilst at the

other extreme hot and dry conditions in summer can result in too rapid curing.

1. Cementitious

Products Slow Curing.

2. Efflorescence

affect (Due to increased water residence times as a result of slowed

evaporation, efflorescence can also be increased in cement based products. Efflorescence

is a deposit of water soluble salts from the cementitious components which are

drawn out by the water and then deposit at the surface when the water evaporates.

Premature sealing can exacerbate this effect.

3. Resin

based products - Slow Curing: These products cure by a chemical reaction

between two components and this reaction is slowed or halted by cold conditions.

The viscosity of the resins can also increase making effective mixing difficult.

Water based epoxies can display increased drying times and apparent stickiness

due to decreased rates of water evaporation.

4. Store the products between 5 – 30 Deg C

in the original unopened containers up to the time as specified by the

manufacturer. If climate is too cold, additional polythene sheets shall be used to protect the products.

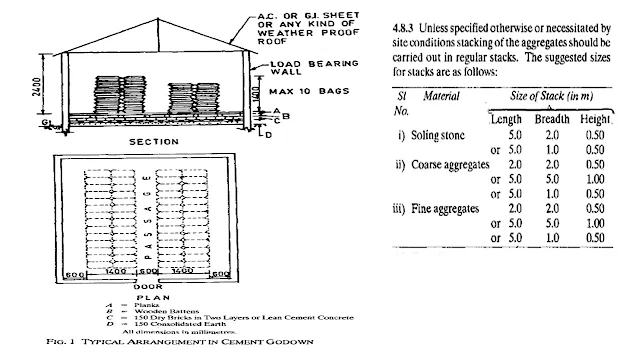

Let see what does IS 4082 - says about the stacking and storage of construction materials and components at site:

Typical arrangement of powder like materials:

Let see some on-site images:

Take notice of safety labels on containers and ensure safe storage of products site. Always store sheet products standing up-right, on pallets to prevent roll distortion. Keep the product exactly as per the arrow mark – up / down. Solvent based products (including M/T drums stored out of direct sunlight.

Hardener product part, starts freezing at 14 Deg C. Such products need to be warmed to temperature of 40 Deg C and thoroughly mixed before mixing with other components. Do not heat the product for more than 40 Deg C as discoloration and dimerization may occur. Overheating of product, may lead to explosive of pale / can. Vice-versa, such products stored at high temperatures may cause in release of Nitrogen / Carbon / Oxygen gas and viscosity varies.

Resin part materials are of many more kind, so we not just discuss in the open form. It is always better to seek the knowledge from the manufacturer’s how to protect the product and if get affected by the temperature, what shall be the next course of action—if use it how, if not – how to dispose them.

Products shall not be in cold temperature say, below 10 Deg C. Minimum 10 Deg and less than 35-40 Deg C. Use Halogen lights to bring the place temperature to normal temperature condition. Products used at below or above this temperature, the chemical action will be affected and product pot life, setting time, flowability will be affected and accordingly final results may vary.

If not protected properly, lumps may

form in the power part of the product.

Water mixable products shall be used

with normal temperature water or heated water. But, water to be used shall not

have temperature more than 21 Dec C. Use Halogen lights to bring the working

place temperature to normal temperature condition.

Use rapid set adhesives to reduce cure times. Increase the amount of ventilation by the use of fans which will raise the rate of evaporation.

b. Hot climate: Hot climate is useful for slow drying membranes products. However the air must not be supplied by a heater as this can cause cracking and should only be used on floor levelling products after the material has hard cured.

1. Cementitious

Products Premature Curing: The maximum recommended temperature for the use is 35

Deg C and summer temperatures can easily exceed this. Products cure faster in

hot weather due to the increased reaction rate of the components. This means

that flow or working times / viscosity will be reduced, and tile adhesives will

have shorter open times before skinning.

2. Substrate /

surface get hot: Dark coloured surfaces exposed to direct sun on a hot day can

reach 50 to 80 Deg C. Concrete substrates can act as heat sinks and hold high temperatures

after the air temperature has fallen.

3. Rapid

Evaporation and Poor Bonding: Increased evaporation means the water / liquid

part escapes from the applied product before curing reactions have a chance to

complete, resulting in weak bonds. Highly dried out substrates can absorb water

/ liquid from the applied product they can skin at the interface with the

substrate preventing penetration into substrate and reduced bonding strengths.

4. Resin products

Premature Curing & Slumping: Epoxy products can cure very rapidly at

increased temperatures, especially where full packs has been mixed and

generates its own heat of reaction which significantly reduces pot life. These

materials can also become less viscous and slump when applied on vertical

surfaces.

5. Blistering of

Membrane Products: Liquid membrane products can skin rapidly and prevent the

underlying moisture from escaping. If the substrate is impervious, blistering

can occurs or poor bonding may result.

Tips:

Mixing of products

needs to be done quickly using mechanical machines. Arrange air conditioning.

Externally, only work in the cooler morning or late afternoon hours and do not

lay materials in areas exposed to direct hot sun. Use the maximum quantity of water

for mixing as per products TDS. Use cool water drawn from pipes or taps, water not

exposed to the sun. Water chilled by ice can be used, but the ice must be melt

and the temperature should not be below 10 Deg C. Mix small batches of material

and only work on an area that can be covered before initial cure or skinning

occurs. Surfaces can be lightly sprayed with water or covered with damp cloth (get

confirmation from manufacturer). Properly prime the surface to minimise

excessive absorption of moisture, rising pin holes, etc. Products like bondings

shall be re-applied if dries out. Don’t rework on the applied products which is

crossed the initial setting.

During the installation, factor increased drying times between each step in the job. If the daytime temperature is acceptable, but may drop significantly at night, only use products until around midday to allow the material to form an initial set prior to the onset of cold temperatures at night.

2. Humidity:

Resinous (specially solvent products of epoxy and PU) will not bond to the surface applied at high humid conditions.

3. Moisture: The nominal moisture vapour transmission rate of 15gm/m²/24 hours is considered to be the maximum permitted for resilient flooring as per the requirements of AS2870 for dampproofing of floors. Hence we need to maintain the vapour transmission rate well below.

4. Surface nature:

b.Porous surface

c. Non - Porous surface:

d. Damp surface:

e. Weak top surface: Week surface will not have ability to hold the product in position at the chemically curing time of the product. Epoxy and PU like resinous products will have great tensile strength and take the surface layer and peel up. cementitious products, may have initial good bond but in the long time frame, they also will de-bond by taking the week matrix surface.

f. Smooth surface:

5. Chemicals:

This blog is under construction….. will

be finalized very soon.