Nothing

is static. It is known to everyone that everything in this world moves at its

own speed or due to its properties and it is especially true in buildings.

Concrete and mortar expand and contracts so do with wood and other building

materials also. Hence, the basic answer is the movement and it is very

important to accommodate this movement or else this movement will cause the

failure of the materials installed. Here are some of the failures caused by the

movement:-

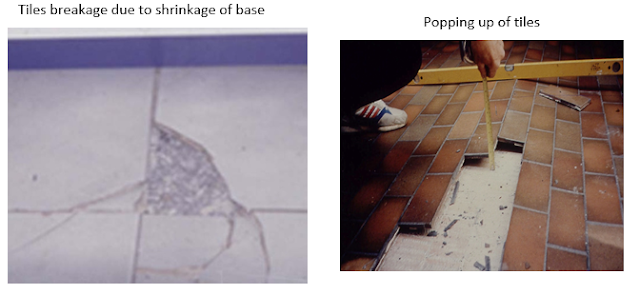

In the

above photos, it is observable that the tiles/stones are installed without joint

gaps and the installed tiles/ stones are unable to accommodate the movements,

as a result, debonding and popping up occurs.

What makes the tiles/stones to move?

The tiles

/ stones fixed on the wall/floor will also make movement due to many reasons.

The following are a few reasons which make the installed tiles/stones to move:-

Physical Building Movement: This is the movement of vibration and deflection

caused by the process of installation of other building application /

materials. This type of movement is the most common and will lead to failure if

the proper measures are not implemented.

Shrinkage of Concrete / Mortar: Shrinkage of concrete/mortar occurs during the

process of curing and hydration. In today’s world, fast track construction

has become normal to install tiles/stones over new concrete/mortar surfaces

that may not undergo all the shrinkage that it shall. In many cases, you may

see tiles / stones tented up over new installations. The continuous shrinkage

of concrete takes place; as a result the gap is formed in between tiles /

stones and concrete / mortar.

Thermal Movement: The thermal movement includes temperature fluctuations

and changes in the environment. It is easy to understand in case of exterior

applications. All installed tiles / stones are subjected to the continuous

cycle of cooling and heating systems, that heat and cool the air. Moving air

across the installation will cause the temperature to fluctuate and results in

movement.

In

exteriors, imagine an installation exposed to the sun, these installations can

reach surface temperatures up to 140°F (60°C). If a quick rain shower comes and

douses the installation with cool rain. In this instance, the surface

temperature will drop to 70°F (21°C) within a few seconds. This type of stress

needs to be accommodated by joints between the tiles / stones or else,

debonding occurs. Interior installations that have skylights or area surrounded

by windows and glass doors needs to be treated as exterior applications.

Moisture: In

some cases, the finish material used shall absorb moisture due to its porosity.

Over time, this absorption of moisture shall cause growth in the finish

material. This growth can lead to loss of bond, if place is not available to

accommodate movement.

Dissimilar Building Materials: The use of dissimilar materials

in the construction is unavoidable and this leads to dissimilar joints. There

will be always movement in between the two different building materials, if they

are not treated well, this movement will transfer to the surface where tiles/

and stones are present.

Is the

paper joint is not enough?

If we

install the tiles / stones side by side, allowed to cure and dry for 24 hrs.

After that, it needs the sealing of joints. For any material, used to grout the

joint gap, shall need some surface to adhere strongly, so that it avoids the

penetration of water, acid and other contaminants to the substrate on which the

tiles / stones are installed. But, in case of paper joints the surface of

adhesion is very small and the provided grout material will goes off making the

place for the contaminants. These contaminants will spread around the edges of

the tiles creating unhygienic surface all over the installation.In all

the above mentioned cases, it is best honour to provide joint gaps between the

tiles/ stones, so that it can accommodate the movements. What if, we provide

the paper joint i.e. installing the tiles/ stones just side by

side?

Whatever

the material which has been used as grout for provided paper joint, will

definitely fails within a short period and causes the effect as shown in the

photos. The weak paper joints will show the way to dirt, moisture, chemicals

and other contaminants to get inside the substrate from the top and may causes

weakness in the substrate.

In order

to avoid the failure of substrate and also to increase the durability of the

tiles / stones, it is strongly recommended to provide the minimum joint of 2 mm

between the tiles / stones and grouted with proper recommended grouts.

Other

uses of tile joint grouting:

Tile and

stone joints will avoid the cracks extension and avoid the damages to the

adjacent tile & stone.

Hides the the imperfection of tile & stone edges.

Improves

the look, beauty/handsomeness, and appearance…

Accommodates

the movement.

Provides the easy cleanable surface, hence no chance of place to mould growth.

Many thanks to google.com, doc4242, dindoc, from where the details have been collected.

Awesome and excellent post, thanks for this kind of blog that may help a lot for those who wants Sealant & Adhesive Manufacturer In UAE. pls check below our Products.

ReplyDeleteAcrylic Sealant

Alkoxy Silicone Sealant

Construction Silicone Sealant

Fire Stop Acrylic Sealant

Hybrid Sealant

Structural Glazing Silicone Sealants

Silicone Sealants Manufacturers

Hybrid Construction Sealants

Silicone Construction Sealants

Specialty Silicone Sealants

Structural Glazing Sealant

Industrial Adhesives Products In UAE

Contact Adhesive Manufacturer In Dubai

Adhesive Manufacturers In UAE

Adhesive In UAE

Construction Adhesives

Industrial Spray Paints

Cement Based Waterproofing Coating

Industrial Adhesive Tapes

Industrial Adhesive Manufacturers

Cyanoacrylate Adhesive Manufacturers

Contact Adhesive

Construction Adhesive Tapes

Cpvc Suppliers In UAE

Cyanoacrylate Adhesive

Maintaining tile & stone joints grout is crucial for preserving structural integrity, preventing moisture damage, and enhancing aesthetic appeal. Neglect leads to costly repairs.Atlanta Tile Installer

ReplyDelete