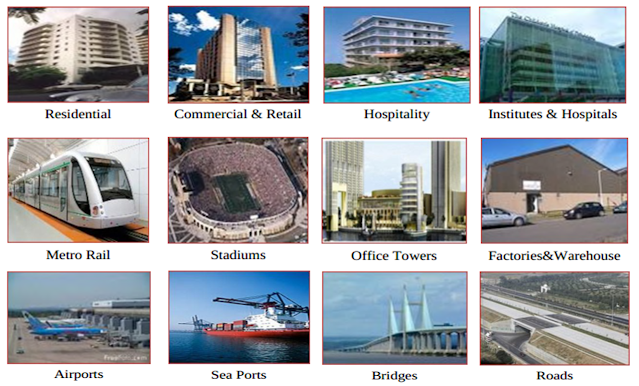

Where all PreFab/Precast Building Construction can be used?

Why do we need PreFab/Precast Building Construction?

1. Saving in concrete and steel

2. Speedy construction

3. Durable construction

4. Ec0-Friendly construction

5. More carpet area

6. No brick work – so no seepage

7. Economic products

8. Less waste from construction sites

9. More efficient and economic production processes

10. Safe and healthy working environment

11. Use of waste materials in products.

1. Fast installation on site

2. Factory/on site-made

3. Guaranteed durability of the delivered product

4. High Compatible: Connection details and joints are thoroughly investigated

5. Provides an instant work platform

6. Reduces noise from building site

7. Comfortable: Carrying Medium for heating and cooling

8. Durable, gets stronger everyday

9. Structurally efficient: easier to go high

10. Has potential to be made in any shape

PreFab/Precast - Common challenges:

1. Excessive use of shutters for casting

2. Curing of casted components

3. Panel joints – needs to be sealed

4. Wall/floor/other joints grouting

5. Anchoring rods

6. Broken edges of structures

7. Open honey combs in structure while casting

8. Bonding agent

9. Tiling installation

10. External painting

11. Waterproofing treatment

a. Toilet blocks

b. Water tanks

c. Effluent treatment tank

d. Terrace area

e. Garden

Some of the important products required to solves the challenges

in PreFab:

- Shuttering

oil

- Curing

compound

- Panel

joints:

- Sheet

applied membrane / Sealing tapes for precast wall panel joints sealing in

basement walls

- Non

shrink grouting at wall/floor and other grouting operations

- Sealant

for panel joints

- Anchoring

grouts additional rods

- Structural

repair mortar of chipped areas

- Cosmetic

repairs mortar

- SBR

based / Epoxy based bonding agent for adjoining

- Tiling

adhesive and joint grouts for POD – bathrooms

- External

paint / sealer

- Waterproofing

- Toilet

area

- Water

tanks waterproofing

- Effluent

treatment tank

- Roof

Waterproofing

- Garden

area

Other important products

- Floor

screed

- Self-levelling

of floor

- Car

park area coatings

No comments:

Post a Comment