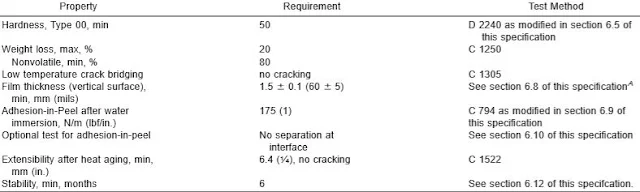

The requirement of High Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane Physical Requirements as per ASTM C 836 - 00 / 03 are as follows:

Testing specimen shall be as follows:

Pull it in a direction normal to the break, at a separation rate of 12.7 mm (0.5 in.)/min, until the distance between the bench marks is exactly 57.2 mm (2.25 in.). Stop the machine and immediately examine the films for any breaks or cracks. There shall not be any cracking or tearing of the film along the opened area on any of the three specimens.

Detail testing procedure is available in ASTM C 1305 and 1305M.

Testing specimen shall be as follows:

Pull it in a direction normal to the break, at a separation rate of 12.7 mm (0.5 in.)/min, until the distance between the bench marks is exactly 57.2 mm (2.25 in.). Stop the machine and immediately examine the films for any breaks or cracks. There shall not be any cracking or tearing of the film along the opened area on any of the three specimens.

Detail testing procedure is available in ASTM C 1305 and 1305M.

Many thanks to google.com and doc88.com from where the details have been collected.

Hi Sir This is Sohel Siddiqui (+91-8080414928), Is there any difference if i need to do a crack bridging ability Test for a elastomeric liquid applied membrane with ASTM C836 or ASTM C1305 , which is a better code for testing of the same & why (need a differentiation on the same)

ReplyDeleteASTM C836/C836M is for Use of High Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane with Separate Wearing Course over the membrane. In general, you can consider, tiling, plastering, concreting, etc.

DeleteWhere as ASTM C1305/C1305M Test Method for Crack Bridging Ability of Liquid-Applied Waterproofing Membrane which will be left exposed, say, façade membrane, external coating, roof terrace coating, etc.

Nice blog, thanks for sharing Hardness test block

ReplyDelete