I provide, technical articles, civil engineering standard, construction standards, testing methods, FAQ, MCQ, new idea, Questions, complaint handling, general notes, Drawings, helping tips, open discussion, decision making idea, where is wrong, what is right, high rise building, tile and adhesive, grouts, concrete repair mortar, epoxy flooring, Polyurethane floorings and many other construction chemical related answers. Helping students, job interview questions, site works, application video.

Main Menu

Total Viewers

Translate

Search This Blog

Wednesday, January 31, 2018

Friday, January 19, 2018

Expansion joints

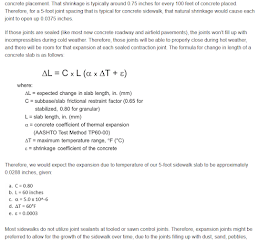

In most buildings, there is some form of restraint that limits how much they can expand or contract. The amount of stress caused by temperature changes depends on how much the temperature changes. Large temperature shifts can cause significant stresses that need to be accounted for during design, while small temperature changes usually have little effect. These stresses happen because a structure changes in size when its temperature changes, especially between points where it is fixed or restrained. To estimate how much a building will expand when temperatures rise, you can multiply the coefficient of concrete expansion (about 12 x 10-6 /℃) by the building's length and the temperature change.

For example, a 200-foot-long building that heats up by 25 degrees Fahrenheit (14 degrees Celsius) will expand by around 3/8 inch (9.5 millimeters). To prevent damage from this expansion, expansion joints are used to allow the structure to grow or shrink without creating too much pressure.

There are many reasons expansion joints are required such as:

2. Structure Shape or Irregularities

3. Isolation of Dissimilar Building Classifications

4. Fire Separation

5. Thermal Movement

2. Floor-to-wall

3. Wall-to-wall

4. Ceiling-to-ceiling

5. Ceiling-to-wall

6. Roof-to-roof

7. Roof-to-wall

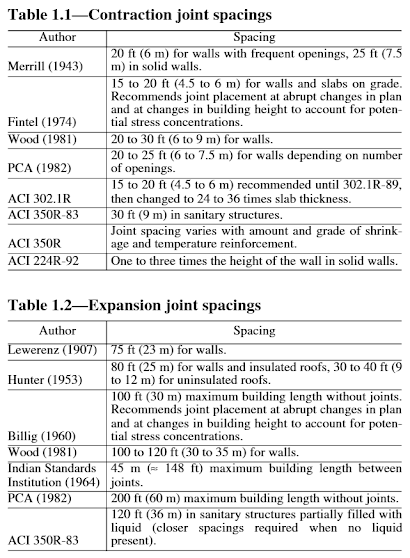

PCA (1982): 200 ft (60 m) maximum building length without joints

ACI 350R-83: 120 ft (36 m) in sanitary structures partially filled with liquid (closer spacings required when no liquid present).

IS 12118-1 similar

As per IS 6494 - expansion joints shall be not be provided in concrete swimming pools, small and medium capacity reservoir....Page No 5.

|

Type |

Control Joints

(Saw-cut/Formed) |

Movement Joints (Expansion

Joints) |

Relevant Standards |

|

Internal Screed Flooring |

4 to 6 meters apart in both directions |

6 to 8 meters apart at structural joints and around columns |

- BS EN 13813 |

|

External Screed Flooring |

3 to 4.5 meters apart |

4.5 to 6 meters apart, aligned with structural joints |

- BS 8204-1 |

|

Underfloor Heating Areas |

Max panel size 40 m² (approx. 6m × 6m) |

Joints aligned with heating zones |

- BS 8204-1 |