The details in this blog has been provided by Mrs Anjali J, Sr Technical Executive - Civil Engineer. Many thanks to her.

Let us know some of the important points about the SAND:

Let us know some of the important points about the SAND:

Here are some of the details regarding the sand used in

construction for Reinforced Cement concrete (RCC) works, Cement Concrete (CC)

works, sand cement mortar for plastering, mortar for brick / stone masonry works,

pointing works, etc,.

Details mentioned are with the refence of:

IS 269

: 2015 Ordinary Portland Cement ‒ Specification

IS 383

: 2016 Specification of Coarse and Fine Aggregate

IS 1542

: 1992 Sand for Plaster—Specification

IS 2386

Part 1 : 1963 Methods of Test for Aggregates for Concrete

IS 2386

Part 2 : 1963 Estimation of deleterious materials and organic impurities

IS 2386

Part 3 : 1963 Specific gravity, density,

voids, absorption and bulking

IS 3812

(part 1) : 2013 Pulverized Fuel Ash –Specification Part 1 : For Use as Pozzolana in Cement,

Cement Mortar and Concrete

IS 4032:1985

Methods of Chemical Analysis of Hydraulic Cements

IS 4082

: 1996 Recommendations on Stacking and Storage of Construction Materials and

Components at site

IS 12089

: 1987 Specification for Granulated Slag

for the Manufacture of Portland Slag Cement

And

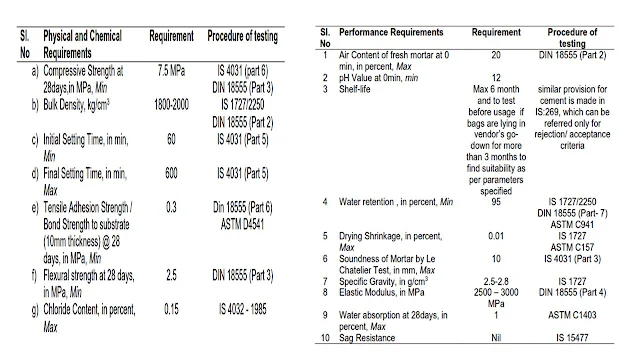

a) DIN 18555

(part 2 to 6) – Testing of mortars containing mineral binders, determination of

consistency flow, compressive strength, setting time, elastic modules and bond strength.

b) ASTM C

941- Standard Test Method for water retentivity of Ground Mixtures.

c) ASTM D

4541 – Standard Test Method for Pull-off strength of Coatings.

d) ASTM C

157 – Standard Test Method for Length Change of Hardened Hydraulic – cement

mortar and concrete

e) ASTM

C-1403 – Standard Test Method for Rate of water Absorption of Masonry Mortars.

f) BS EN

1015-1999 (part 1,8,11,12 &18) – Method of Test for Mortar for masonry.

g) BSEN

998-1-2016 – Specification for mortar for masonry, rendering and plastering mortar.

The sand

shall consist of natural sand, crushed stone sand or crushed gravel sand or a

combination of any of these. The sand shall be hard, durable, clean and free

from contaminants.

The sand

shall not contain any harmful impurities, such as, iron pyrites, alkalies,

salts, coal, mica, shale or similar laminated materials, soft fragments, sea

shells and organic impurities in such quantities as to affect adversely the

hardening, the strength, the durability and the appearance of the plaster or

applied decoration, or to cause corrosion of metal lathing or other metal in

contact with the plaster.

Clay, silt

and dust [determined in accordance with IS 2386 (Part 2)] – Not more than 5

percent by weight.

The average

compressive strength shall be not less than 3 N/mm at 28 days.

The amount

of water for gauging shall be that required to give a flow between 110 to 115

with 25 drops in 15 seconds.

The fineness

modulus of sand shall be not less than 1.4 in case of crushed stone sands and

crushed gravel sands and not less than 1.5 in case of naturally occurring

sands.

Mineral /

Chemical additive shall be made as per the agreement / manufacturer’s

specification.

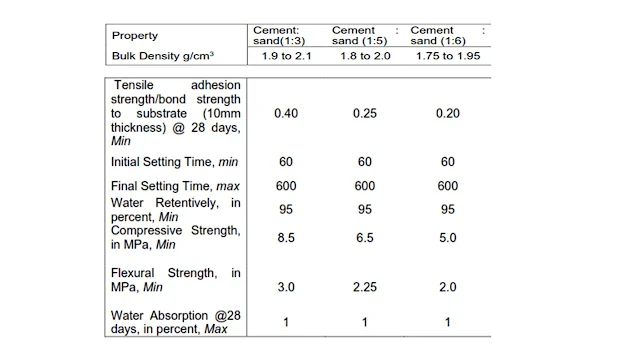

Other than

1:4 mix of CM shall have minimum property of:

ReplyDeletenice post, thank for your information..

P Sand Price in Chennai

M sand Manufacturers in Chennai